Radiation Testing Expertise

Since 2018, QRT has provided radiation evaluation services (TID/SEE/DDD). Building on years of test design, measurement, and analysis know-how, we are continuously collecting data to establish a rigorous correlation between laser-based SEE evaluation and heavy-ion testing. Our goal is to refine models so that laser results can serve as reliable leading indicators for heavy-ion outcomes.

Best-in-Class Device Preprocessing

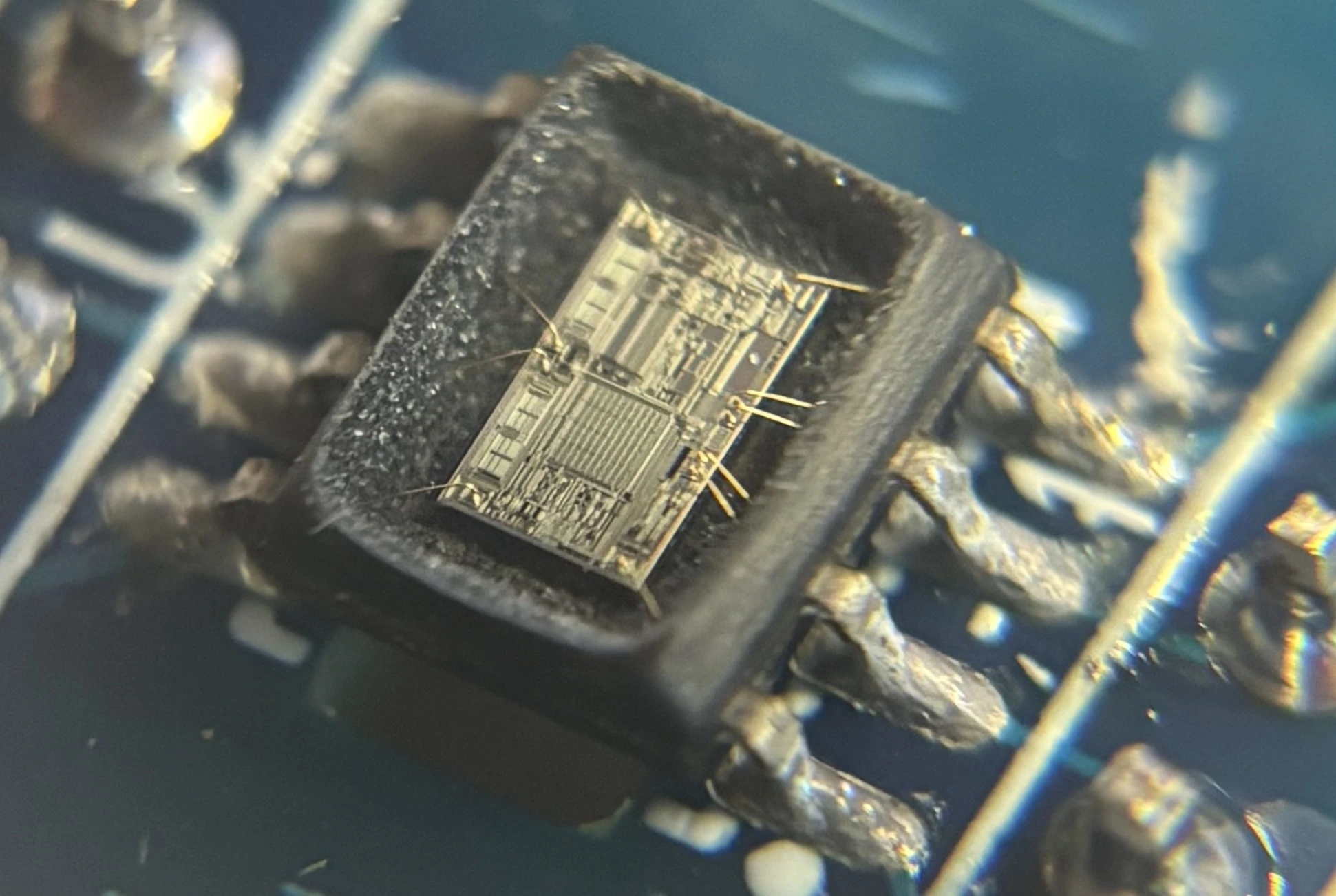

For both heavy-ion and laser evaluations, decapsulation and back-side thinning are essential steps in sample preparation. QRT performs these preprocessing steps in-house rather than outsourcing. Leveraging 40+ years of comprehensive analysis and reliability experience, we deliver preprocessing with consistent, high quality, enabling a reproducible test environment that meets your objectives and timelines. Performing preprocessing and evaluation as a single, integrated workflow minimizes inter-process loss and reduces both lead time and cost.

Decapsulated Device

Combination with Instrumentation

QRT’s laser evaluation integrates not only with our in-house QRT SEE Analysis System (SAS) but also flexibly with platforms such as National Instruments PXI. By combining oscilloscopes, DAQ, and SMU (source measure unit), we synchronize laser conditions and measurements to implement richer test scenarios tailored to each device.

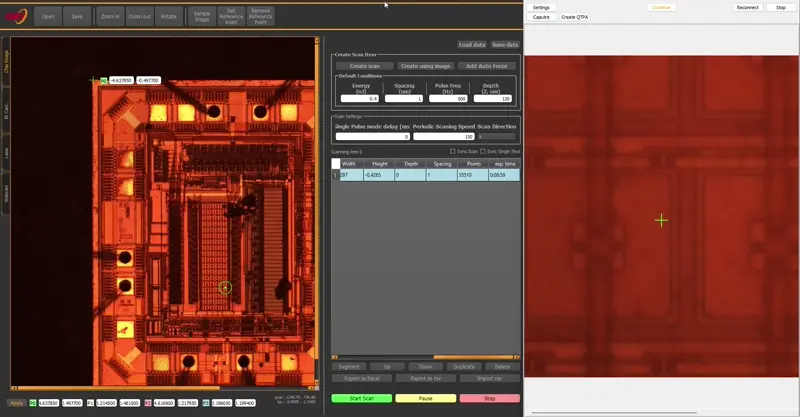

QRT SEE Analysis System (SAS)

10–25% of the cost of heavy-ion testing

Radiation hardness evaluation is mandatory for up-screening, and heavy-ion SEE testing dominates total cost. For the same device, laser-based SEE evaluation typically costs about 10–25% of heavy-ion testing, dramatically easing budget pressure. Because rapid, iterative verification is possible—from early screening through design refinement—you save both budget and lead time.

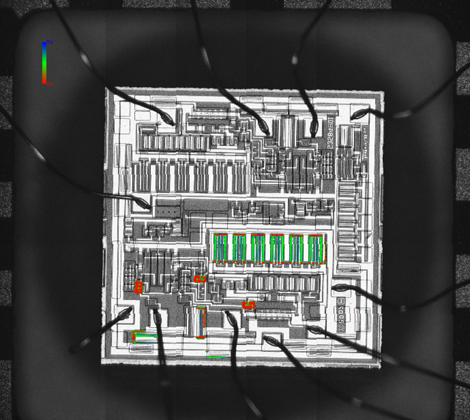

Sensitive Area Analysis

Using a high-precision XYZ stage (nanometer-level control) and laser scanning, QRT precisely irradiates targeted positions on a semiconductor die. This allows us to pinpoint SEE event locations and visualize sensitive areas across the circuit.

Sensitive Area Map

Lab Access Service

QRT’s Laser Testing Lab is powered by our in-house software, QRT-LITE (Laser Irradiation Tools for Evaluation), which delivers more intuitive operation and precise control than competing tools—so even first-time users can set up and run evaluations quickly.

Key capabilities of our in-house software include:

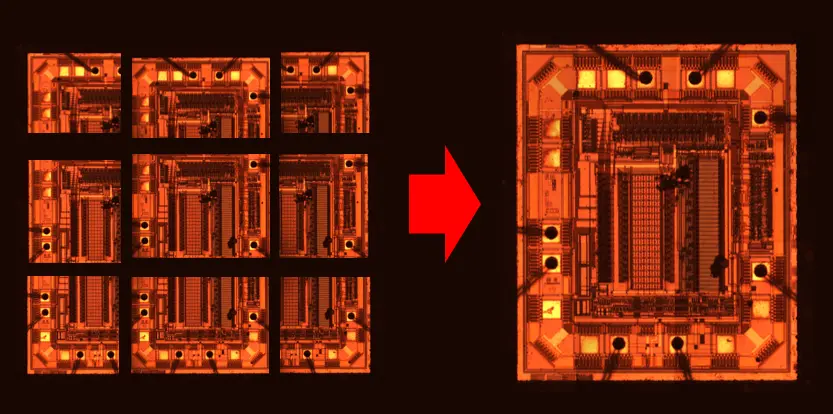

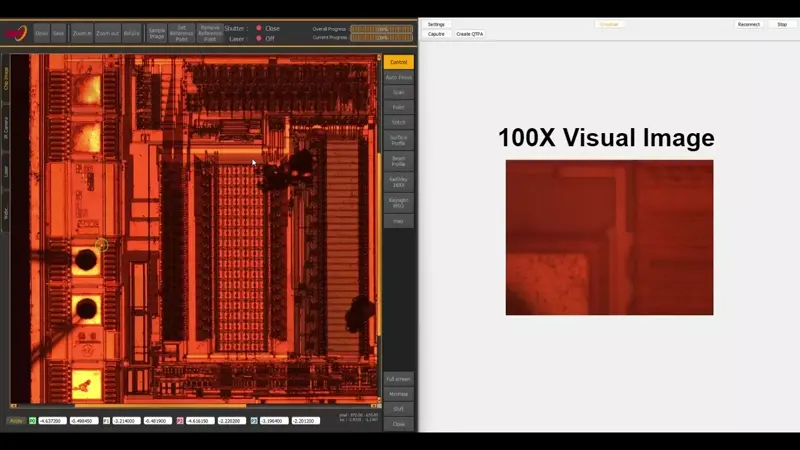

High-Resolution Chip Image

To achieve higher resolution, chip images are captured as multiple tiles and stitched into a single image. QRT-LITE’s Auto Image Scan automates capture and stitching to produce a seamless, high-resolution composite.

Image Stitching Principle

Synchronization of Chip Image and XYZ Stage

For easy operation, QRT-LITE links the stitched high-resolution chip image with the XYZ stage. Clicking a point on the image converts pixel coordinates to the real stage coordinate system and moves the stage automatically to the exact location.

Stage Movement by Clicking on the Chip Image

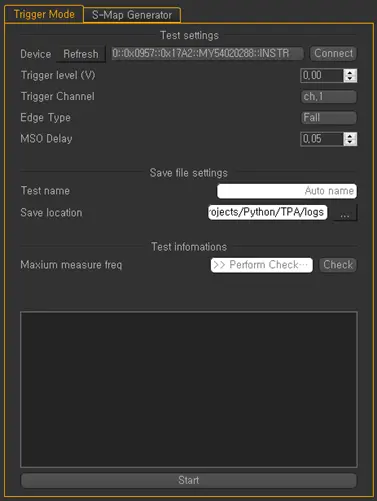

Flexible Integration with Oscilloscope and Source Meter

QRT-LITE connects directly to Keysight oscilloscopes to automatically capture and store transient responses. When a trigger occurs, QRT-LITE immediately receives and records waveforms with timestamps, which can later be mapped to coordinates to create a Sensitive Area Map. Integration with SMU and DAQ enables combined analysis of current/voltage responses.

These features allow simple devices to be evaluated without additional development.

Oscilloscope Integration Panel

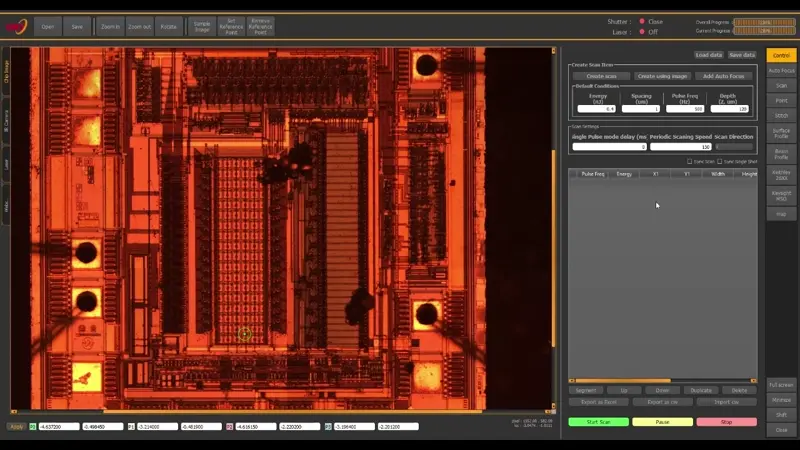

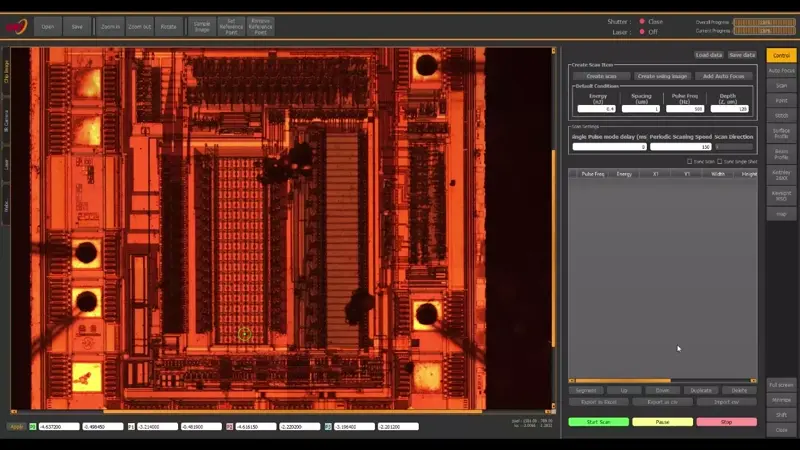

Scheduling

Set coordinates directly or drag to select scan regions; QRT-LITE automatically adds those positions to the Scan List. You can configure per-item laser conditions (e.g., energy, pulse repetition rate), enabling efficient, repeatable evaluation.

Define Scan Regions by Dragging

You can also save and reload previously used settings for one-click reuse.

Import Scan List

Fast Testing

QRT-LITE minimizes latency by optimizing communication and control parameters, bringing out the maximum performance of the hardware. In addition, the system supports a wide pulse repetition range of 1 Hz–1 kHz, enabling faster and more diverse evaluation scenarios depending on your needs.

Speed Demonstration in a Real Evaluation

Related Articles

- Comparison of Band Gaps and Optical Absorption Mechanisms of Semiconductor Substrates

- Analysis of Laser Evaluation Feasibility by Semiconductor Package Type

- Laser Evaluation Based on NASA Documents

- Why Laser Evaluation is Necessary (Cost Perspective)

- SPA vs TPA

- Semiconductor Radiation Hardness Laser Evaluation (Laser Test)