Why Laser Evaluation is Necessary - A Cost Perspective

When deploying commercial off-the-shelf (COTS) components in space systems, up-screening is essential to ensure reliability.

These activities include mechanical, electrical, and environmental tests-and, critically, radiation-hardness evaluations.

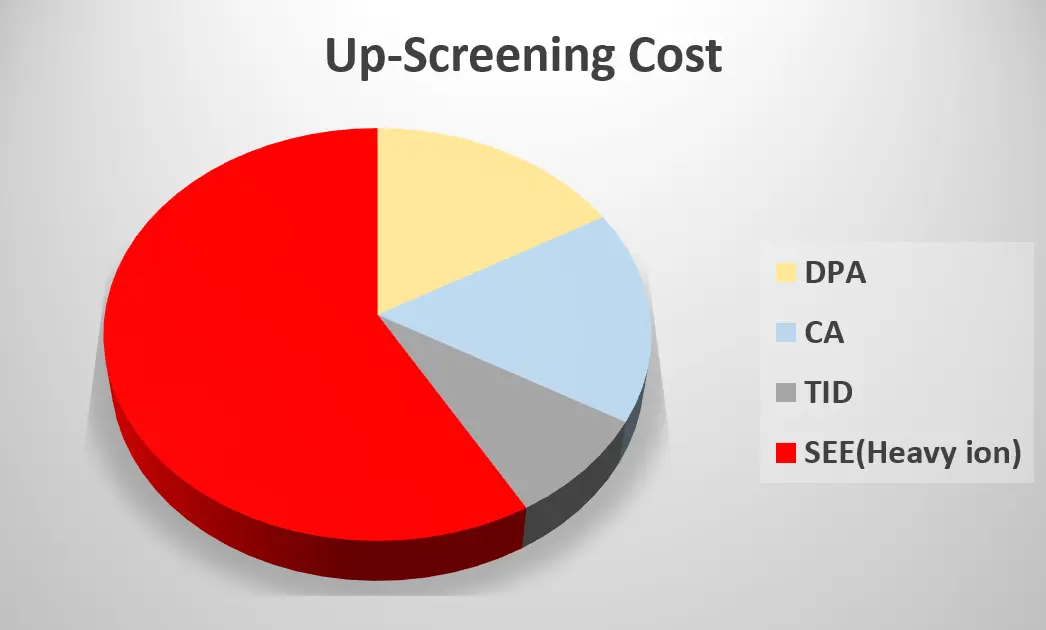

Among all up-screening steps, the single-event effect (SEE) test-particularly when using heavy-ion beams-accounts for a disproportionately large share of total cost.

As shown in the chart, heavy-ion-based SEE testing dominates the cost structure, exceeding other evaluation categories such as TID (total ionizing dose), DPA (destructive physical analysis), and CA (construction analysis). While COTS components carry a lower purchase price than space-grade parts, the cost of heavy-ion SEE testing during up-screening can match-or even exceed-the cost of using qualified space-grade components.

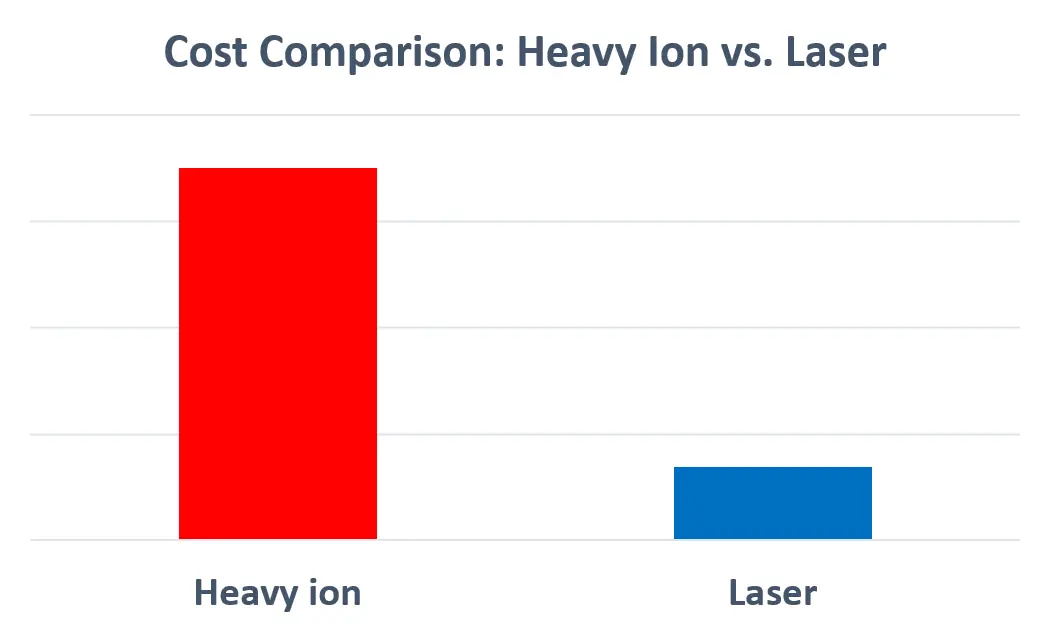

This comparison illustrates the contrast: heavy-ion SEE testing incurs substantial expense even for a single run.

By contrast, laser-based testing of the same device is typically about four times less expensive.

This can erode the expected cost savings from using COTS, reducing overall program efficiency in some cases.

To address this, many teams supplement-or, where appropriate, replace-heavy-ion tests with laser-based SEE evaluations.

Because radiation-effects testing-especially SEE-is often the cost driver in up-screening, laser testing offers a compelling way to preserve test coverage while significantly reducing cost.

Related Articles

- SPA vs TPA

- Laser Evaluation Based on NASA Documents

- Semiconductor Radiation Hardness Laser Evaluation (Laser Test)

- Analysis of Laser Evaluation Feasibility by Semiconductor Package Type

- Comparison of Band Gaps and Optical Absorption Mechanisms of Semiconductor Substrates

- Strengths of QRT Laser Testing