In domains that demand high reliability-space, aerospace, and defense-the quality and reliability of each component critically affect overall system performance and mission safety. Equipping a system solely with fully qualified space-grade parts is often impractical due to cost, supply, and technical constraints. As a result, the use of COTS (Commercial-Off-The-Shelf) parts can be unavoidable. In such cases, Up-Screening is applied to verify whether these parts can achieve the reliability needed for space environments.

What is Up-Screening (Up-Screen)?

Up-Screening refers to additional testing and evaluation performed on parts that are not originally space-grade (e.g., COTS, automotive grade) to reduce risk and determine their suitability for use in high-reliability environments.

It goes beyond basic functionality checks to assess temperature behavior, electrical performance, lifetime, and failure rates against space product assurance expectations. It’s important to note that Up-Screening does not “promote” a part’s manufacturer grade. It reduces risk through extra testing; it does not grant an official space-grade classification from the manufacturer.

Up-Screening (Up-Screen) Items

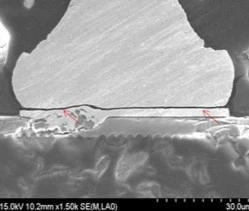

CA / DPA

Covers external marking/lead finish checks and detailed destructive physical analysis to examine internal structure, materials, and workmanship (e.g., die chipping/contamination, wire-bond quality, intermetallics).

Mechanical Test

Verifies robustness against launch/space mechanical stresses such as vibration, mechanical shock, thermal/pressure-related loads.

Reliability Test

Targets early-life failure removal and long-term stability (e.g., burn-in, life testing, temperature cycling).

Radiation Test

Evaluates tolerance to the space radiation environment (electrons, protons, heavy ions, gamma), including TID, SEE, and displacement damage (DDD/TNID).

Up-Screening (Up-Screen) Process

1. Mission/Risk Definition & Test Plan

- Define environmental, lifetime, availability, and radiation needs; document screening items, conditions, sample sizes (incl. PDA), and acceptance criteria.

2. Part Selection & Data Collection

- Gather datasheets, process/grade (e.g., AEC-Q), reliability reports, and supply-chain information.

3. Non-Destructive Screening

- Perform external/marking checks, pre/post electrical measurements, X-ray/CSAM to assure integrity before assembly.

4. Environmental Stress Screening

- Apply temperature cycling, burn-in, and-if needed-thermal vacuum/vibration/shock to surface latent defects and check parameter stability.

5. Radiation Evaluation

- Depending on mission, apply TID (gamma), SEE (heavy ion/proton), and DDD (proton/neutron) per the project/agency RHA plan.

6. Lot Acceptance Test (LAT) & DPA

- Verify lot-to-lot consistency via representative LAT (electrical/environmental) and confirm internal workmanship/process via DPA.

7. Documentation, Traceability & Disposition

- Compile pre/post measurements, failure modes, rework status, compliance to acceptance criteria, and residual risk into SCDs and test reports.

QRT Up-Screening (Up-Screen) Service

QRT provides comprehensive Up-Screening that includes:

- DPA (Destructive Physical Analysis)

- CA (Construction Analysis)

- Mechanical Testing

- Reliability Testing

- Evaluation of TID, Displacement Damage (DD), and Single Event Effects (SEE)

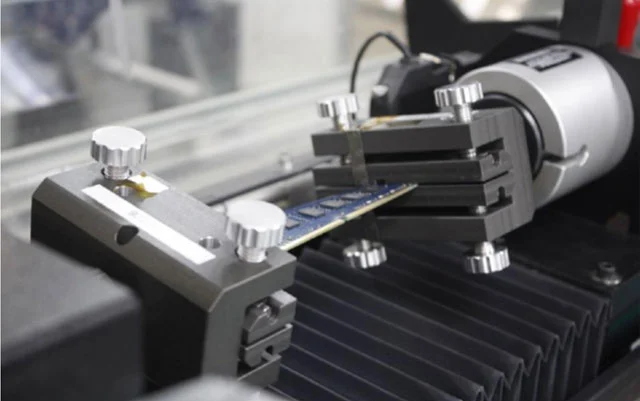

- Pulsed Laser SEE Test

- Mission/environment-tailored technical consulting

- Custom evaluation boards and test services to meet customer needs

QRT offers a complete Up-Screening solution-covering DPA/CA, radiation hardness evaluations (TID/SEE), and expert consulting-tailored to your requirements.