External Visual Inspection

External Visual Inspection is a basic check for external defects on the body, markings, and leads.

Following ESCC 2055000 and 2059000, 10 samples are inspected for any defects.

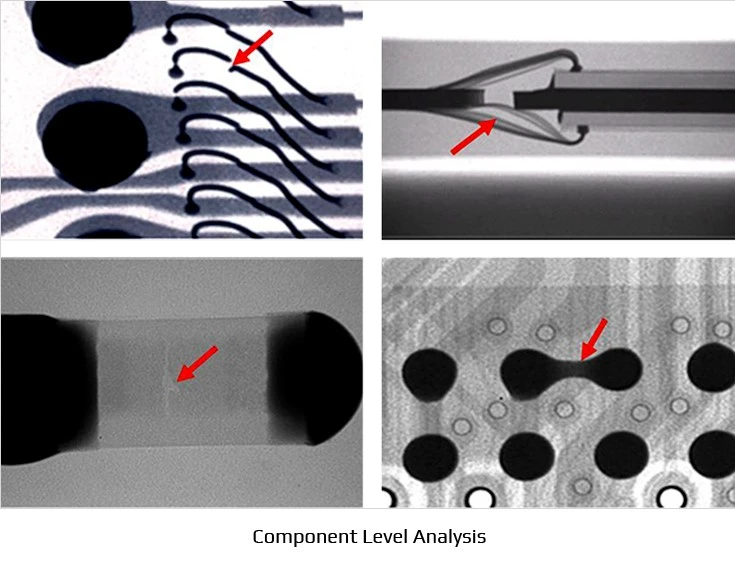

X-ray

X-ray provides non-destructive inspection of internal structures and is performed on 100% of parts.

Tests follow MIL-STD-750 and MIL-STD-883, and exposure is controlled to avoid any reliability impact.

Solderability

This test evaluates how well solder forms reliable joints with a component's leads and terminals.

Surface degradation on leads/terminals can reduce overall soldering quality during assembly and,

in turn, become a root cause of failures in the field.

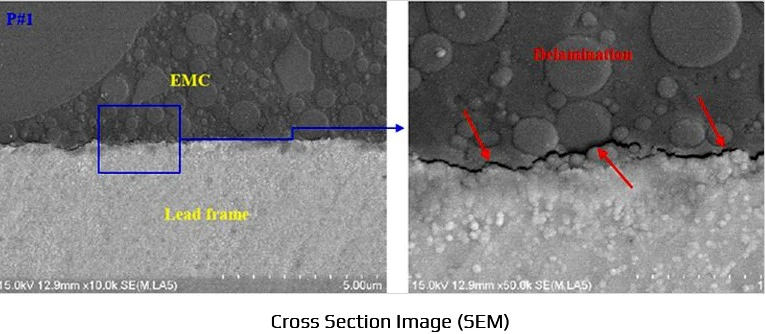

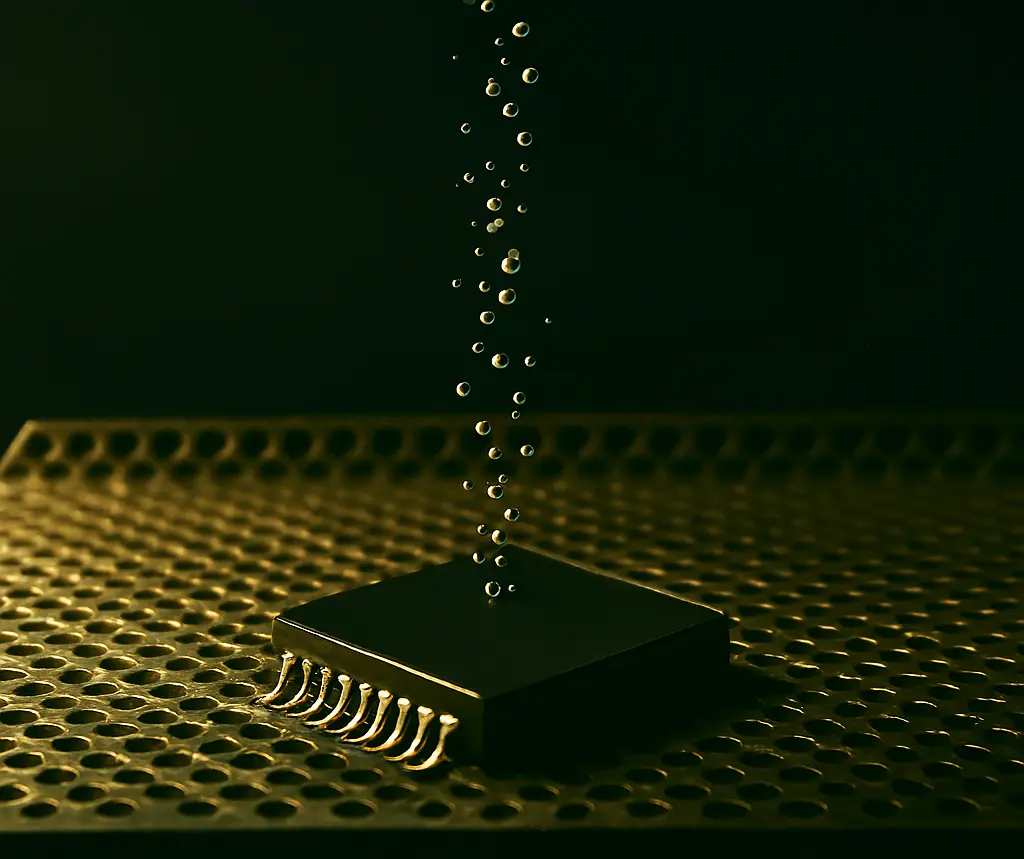

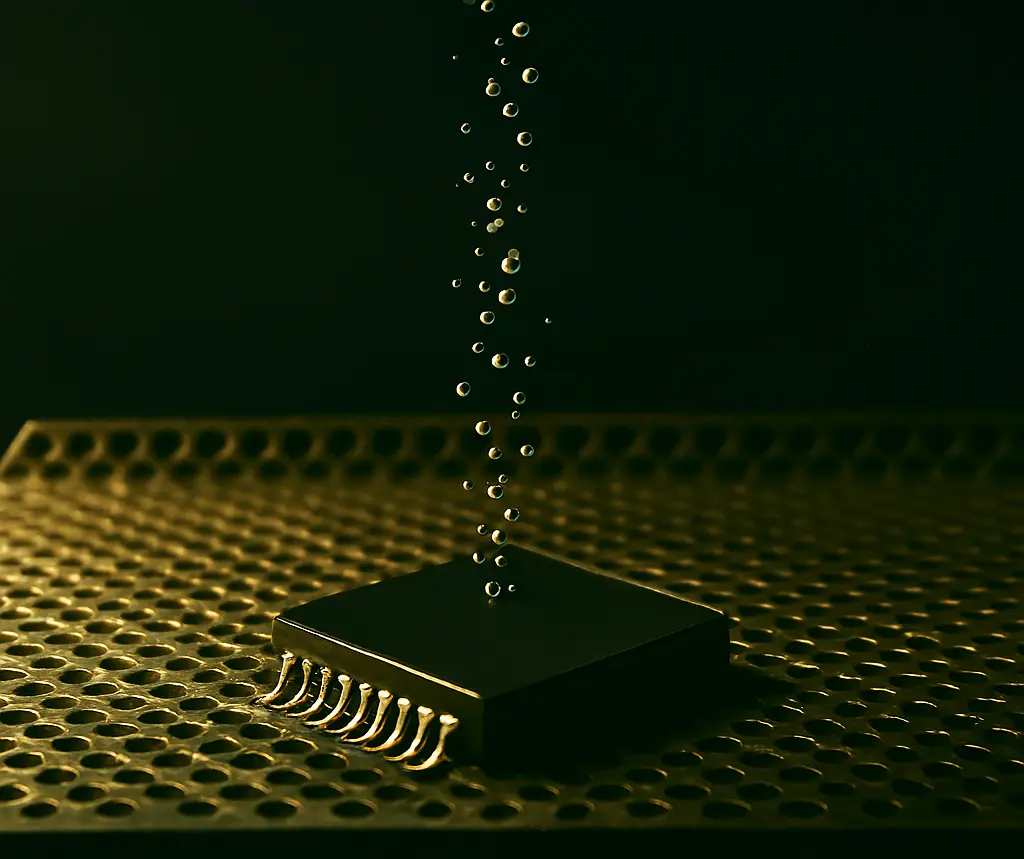

C-SAM

C-SAM is a non-destructive scan using ultra-sound to detect delamination and voids in plastic packages. In line with

JEDEC J-STD-020, it is performed between electrical tests and preconditioning.

Electrical Test

Electrical testing verifies that parameters are within specification before and after

reliability stress. In this test all parts are evaluated at 25 °C, recording key quantitative values for comparison with

post-stress results.

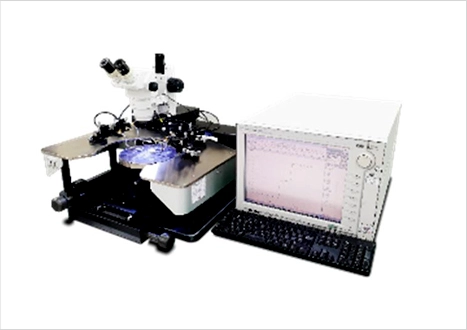

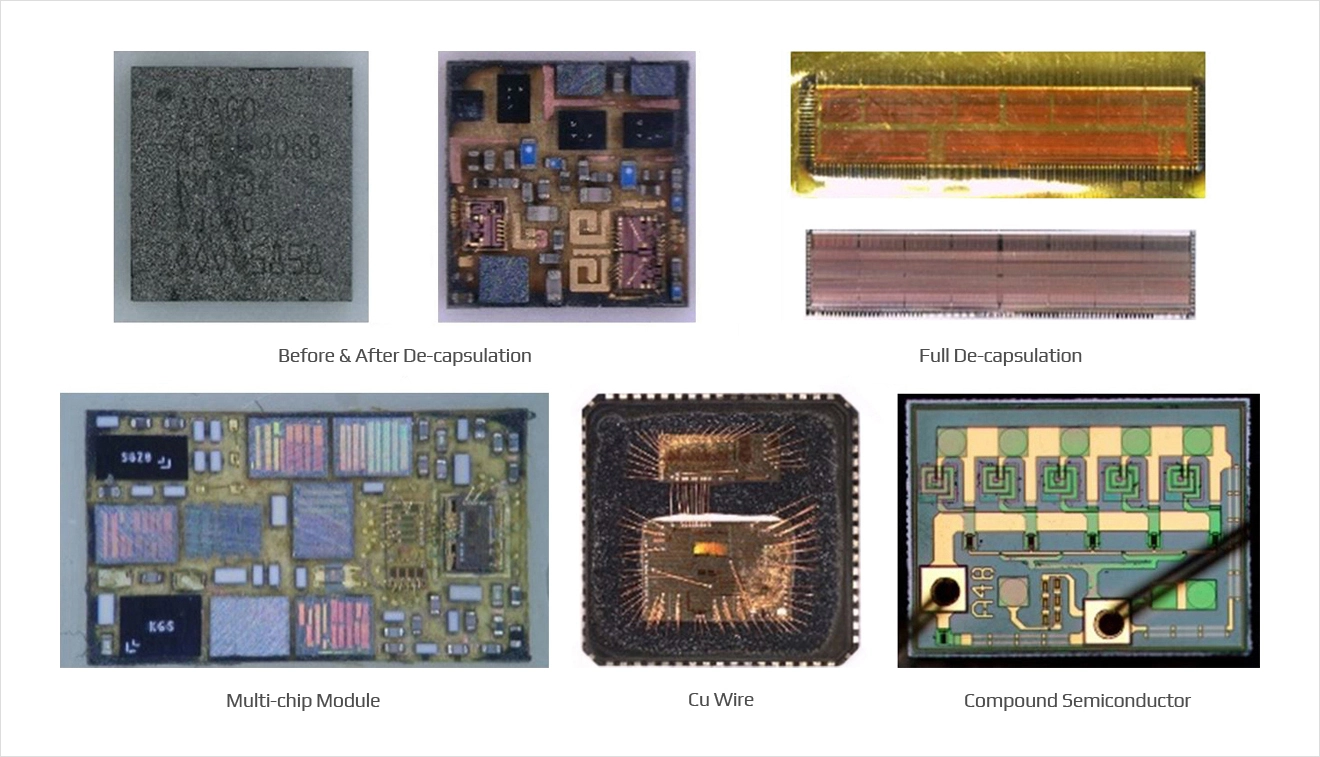

Internal Visual Inspection

Internal Visual Inspection is a destructive analysis step to directly assess internal structures (die,

bonding, leadframe, etc.) for build quality and defects. It is a crucial stage of DPA (Destructive

Physical Analysis) used for reliability assurance and counterfeit screening. Specimens require careful

decapsulation to expose the die without damaging wires or pads. QRT service decapsulation not only for EMC

but also glass and metal-encapsulated devices.

Die & Bond Shear Test

These tests evaluate the durability of joints against shear stresses that may occur during manufacturing,

handling, testing, transport, and use. Wire bond shear and pull are performed after decapsulation. Solder

ball shear applies to all SMT packages except flip-chip and is conducted prior to PCB assembly.

Each ball should be sheared individually and shear stress and failure modes are captured and analyzed.

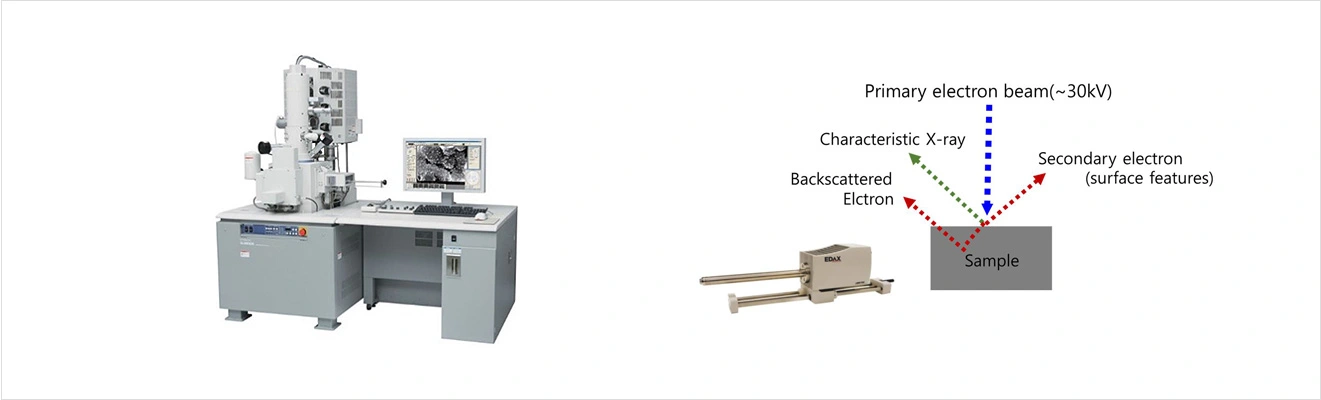

SEM Inspection

SEM (Scanning Electron Microscopy) provides high-resolution imaging for DPA and quality analyses. Typical

checks include wire-to-lead connections (cracks, lifts, contamination), the integrity of the surface

passivation (glassivation) layer, and interconnect condition (cracks, deformation, porosity).

Glassivation Integrity

This test verifies the quality of the dielectric protective layer over metal lines. Through controlled

chemical etch, we confirm clean exposure of metal without damage-assessing both glassivation condition and

etch process suitability.

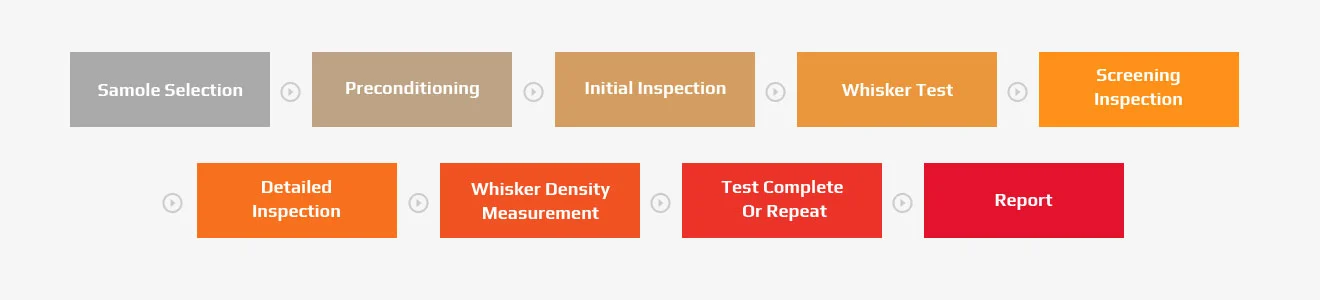

Lead Finish Analysis & Pure-Tin Identification

This test identifies the metallization of leads (e.g., Sn, Pb, Ni, Au, Cu combinations) and assesses RoHS compliance.

Pure tin finishes can grow conductive whiskers over time, risking shorts; therefore, detecting pure-Sn is

crucial for high-reliability applications in space/aviation/defense.

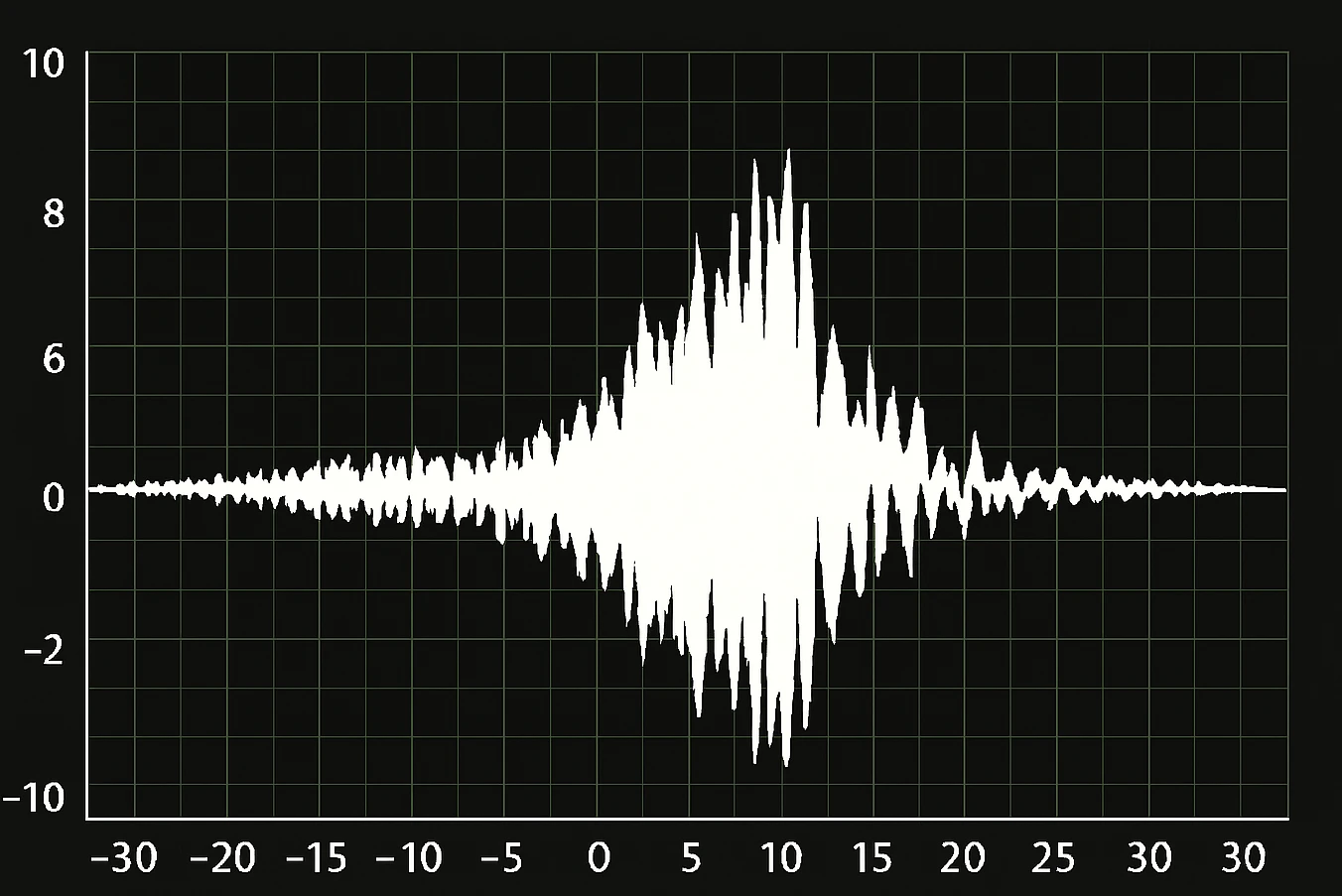

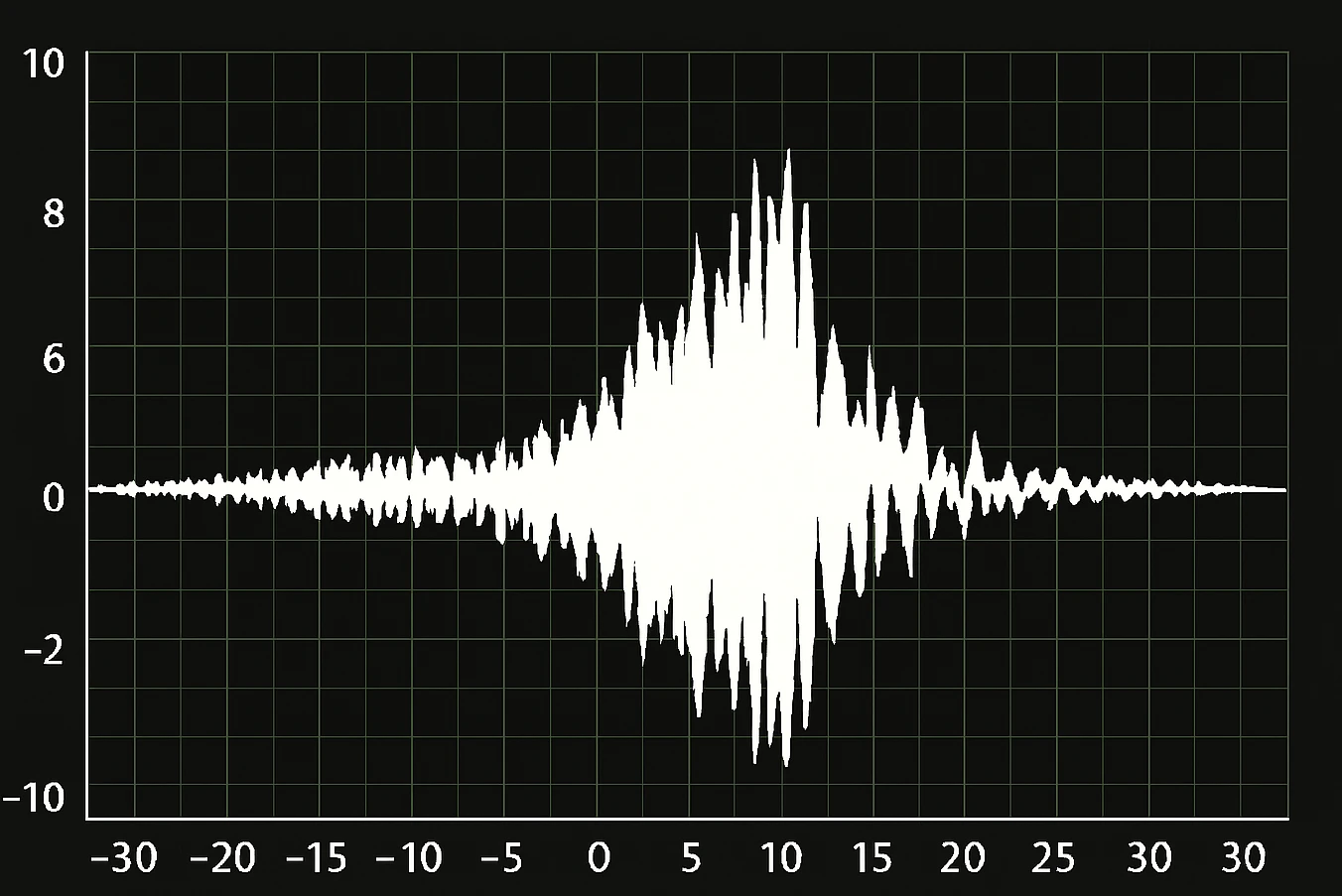

PIND (Particle Impact Noise Detection) Test

PIND detects loose particles (metal/ceramic debris) inside hermetic cavity packages (metal cans, ceramic

DIP/CLCC, hermetic BGA, etc.). The device is subjected to vibration/impact pulses, and an acoustic/velocity

transducer captures signals generated as particles strike the case walls. We currently offer this via

partner labs, with in-house capability planned for 2026.

PIND Test

PIND Test

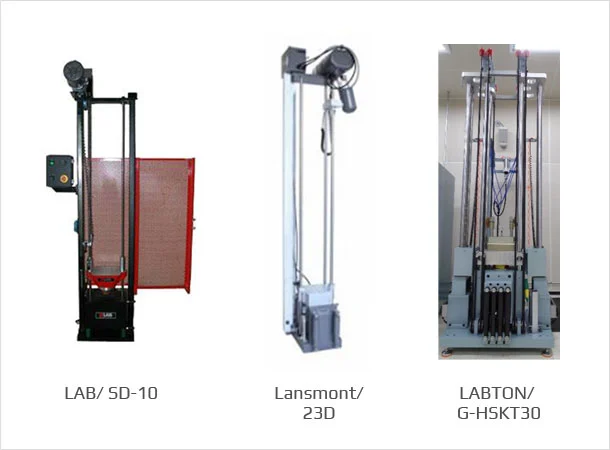

Mechanical Shocks

This test evaluates a component's ability to withstand mechanical shocks from drops, handling, and

transportation without physical damage. The specimen does not impact directly; instead, we apply rapid

acceleration changes to induce stress (e.g., the transient acceleration transmitted to door-mounted

components when a door slams).

Vibrations

This test confirms structural and functional robustness under vibrations encountered during transport and normal

equipment operation. An electrodynamic shaker generates the required amplitude, frequency, and acceleration.

Sine vibration is used to identify resonances; random vibration reproduces real-world profiles.

Constant Acceleration

Constant Acceleration test evaluates how cavity-type semiconductor packages tolerate centrifugal stress. It helps

reveal structural and mechanical weaknesses that may not surface in shock or vibration. Depending on stress

level, it can be used as a destructive limit test to determine mechanical margins, or as a screen to remove

units with below-normal mechanical strength.

Thermal Shock

Thermal Shock evaluates 1) whether parts tolerate extreme hot/cold conditions and 2) how repeated exposure

to hot/cold conditions affects them. Failures driven by repetitive thermo-mechanical is called fatigue failure,

and thermal cycling accelerates such mechanisms. The difference between TC(temperature cycling) and TS is that TC uses air as the medium,

TS(thermal shock) uses liquid as a medium.

Seal Test

For Aerospace and defense applications, long-term stability requires robust hermeticity to keep moisture

and contaminants out. Seal Test quantifies hermetic quality. We first screen out large leaks (Gross Leak)

using immersion/heating/pressurization, then measure down to very small leak rates (Fine Leak) with helium

mass spectrometry against the specified acceptance limit (LR). Conditions are calculated from

internal volume and mission reliability needs. We currently offer this via

partner labs, with in-house capability planned for 2026.

Seal Test

Seal Test

Preconditioning

Preconditioning reproduces handling, storage, and reflow steps prior to PCB assembly to ensure devices

remain fully functional after soldering. In short, it screens for issues that may arise during board-level

manufacturing before shipment of the final product.

Highly Accelerated Stress Test

Electronics frequently operate in hot and humid conditions. When hermeticity is insufficient, internal

metals can corrode or suffer ionic migration. HAST/THB evaluate a device's robustness to these mechanisms.

After preconditioning, we perform either 96 hours HAST or 1000 hours THB, and verify no functional

failures before/after stress.

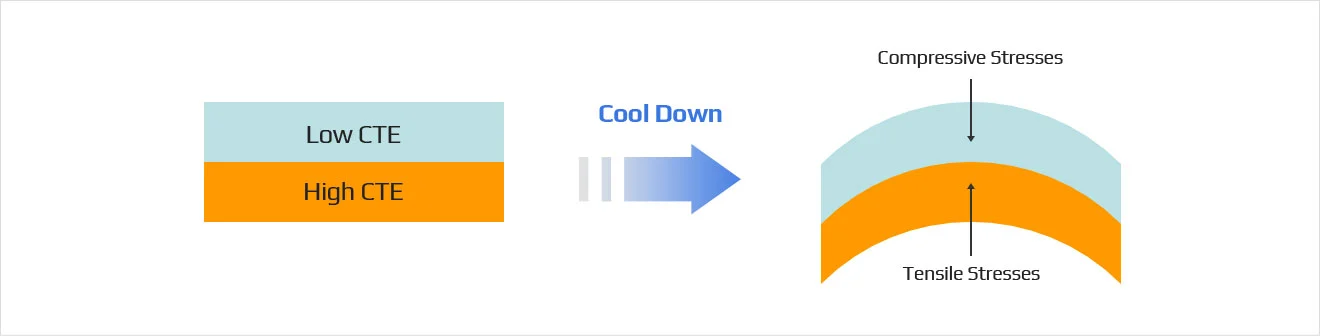

Thermal Cycling

Thermal Cycling validates survivability under repeated extreme thermal cycling (-55 °C to +125 °C). It is used to

uncover defects caused by differential expansion and contraction in real applications. Preconditioning is

required before this test. We check for physical/functional defects with electrical tests at a room temperature after 500 or more cycles.

Life Test, Burn-in

Life Test operates devices at elevated temperature for 2000+ hours to ensure long-term functionality and

performance stability. It is essential for lifetime prediction and is accompanied by MIL-standard electrical

characterization.

Burn-in applies thermal and electrical stress to precipitate and remove infant-mortality failures. Typical

conditions are 125 °C/240 h, 105 °C/445 h, or 85 °C/885 h in accordance with MIL-STD-750/883.

Test temperature and number of device samples must be considered with device specifications.

Anti-oxidation handling is also required after the burn-in process.

Total Ionizing Dose

TID is the total energy absorbed when a device is exposed to radiation (gamma, X-ray, electron, etc.) over

time. Accumulation can gradually shift parameters or impair function. QRT performs TID testing using

domestic (Korean) gamma-ray facilities.

Displacement Damage Dose

Displacement Damage (DD) occurs in the bulk of a semiconductor, unlike Total Ionizing Dose (TID),

which is confined to the interface. This damage, which affects the entire bulk, can alter the electrical,

optical, and thermal properties of the semiconductor, leading to degraded device performance or even

functional failure. QRT performs Displacement Damage testing using domestic (Korean) proton facilities.

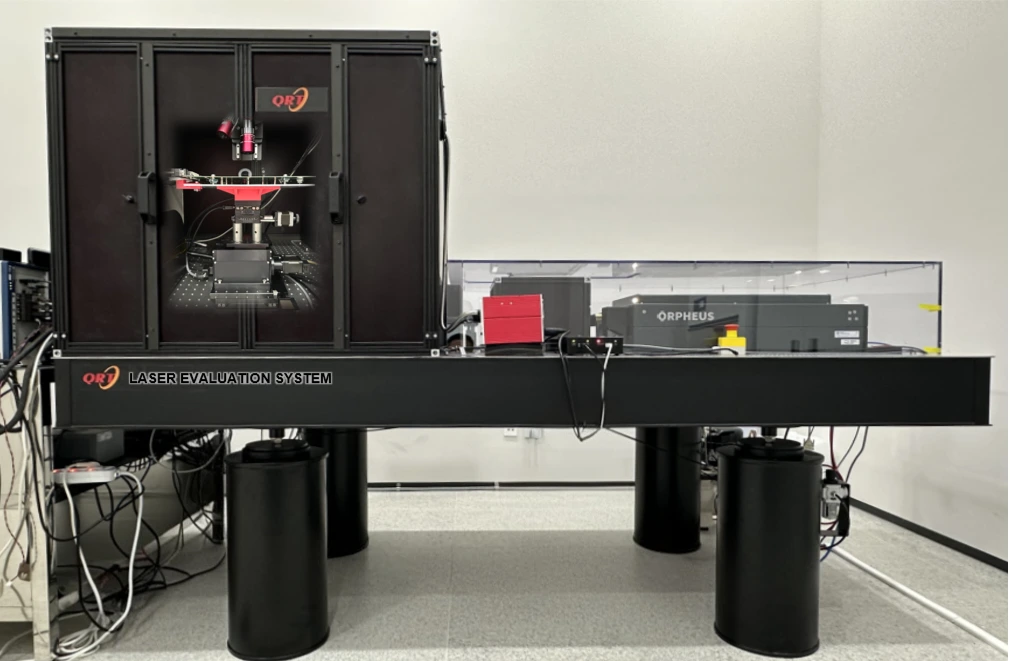

Single Event Effects - Pulsed Laser

Pulsed-laser SEE testing (PLSEE) uses a femtosecond pulsed laser to emulate how space radiation affects

semiconductor devices, providing a rapid, high-resolution alternative/complement to conventional beam tests.

With years of hands-on experience, QRT supports both SPA (single-photon absorption) and TPA (two-photon

absorption) modes. With Pulsed-laser, SEE analysis and design verification are available at QRT.

Single Event Effects - Heavy Ion

SEEs occur when radiation (protons, neutrons, heavy ions, gamma, etc.) ionizes the medium as it passes

through a device. If the generated charge reaches a sensitive region with sufficient magnitude to change

state, an error occurs. Most SEEs are non-destructive and temporary; normal operation resumes after a

reset or power cycle.

PIND Test

PIND Test

Seal Test

Seal Test