Space Product Assurance — EEE (Electrical, Electronic and Electromechanical) Components

EEE components are a comprehensive category covering Electrical, Electronic, and Electromechanical parts—the foundational building blocks used across the space industry. These components determine the performance and reliability of spacecraft such as satellites, probes, and launch vehicles, and must operate reliably under extreme environments.

Space Product Assurance encompasses the processes and activities that ensure these EEE parts deliver the quality, reliability, and safety required for successful space missions.

The globally recognized standards for managing space-grade EEE components (space semiconductors) include:

- ESCC (European Space Components Coordination): An ESA-led standardization and certification framework for space EEE parts, developed with European national agencies and industry. It covers part specifications, evaluation and qualification (QPL/EPPL) management, test/verification procedures, and quality assurance requirements to ensure reliability and interoperability across European space programs.

- ECSS (European Cooperation for Space Standardization): A set of formal international space standards jointly developed by ESA, European national agencies, and industry to ensure system quality, reliability, safety, and cost-effectiveness.

- MIL-STD (Military Standard): A U.S. Department of Defense standardization system for military systems, parts, equipment, and processes.

- NTSS (NASA Technical Standards System): NASA’s official repository and portal for technical standards, enabling NASA programs—as well as contractors, labs, universities, and industry partners—to apply common technical baselines and maintain consistency and quality across projects.

These standards comprehensively address testing, certification, procurement, and management of parts, thereby ensuring system-level stability and reliability in space programs.

Europe: ECSS / ESCC Framework

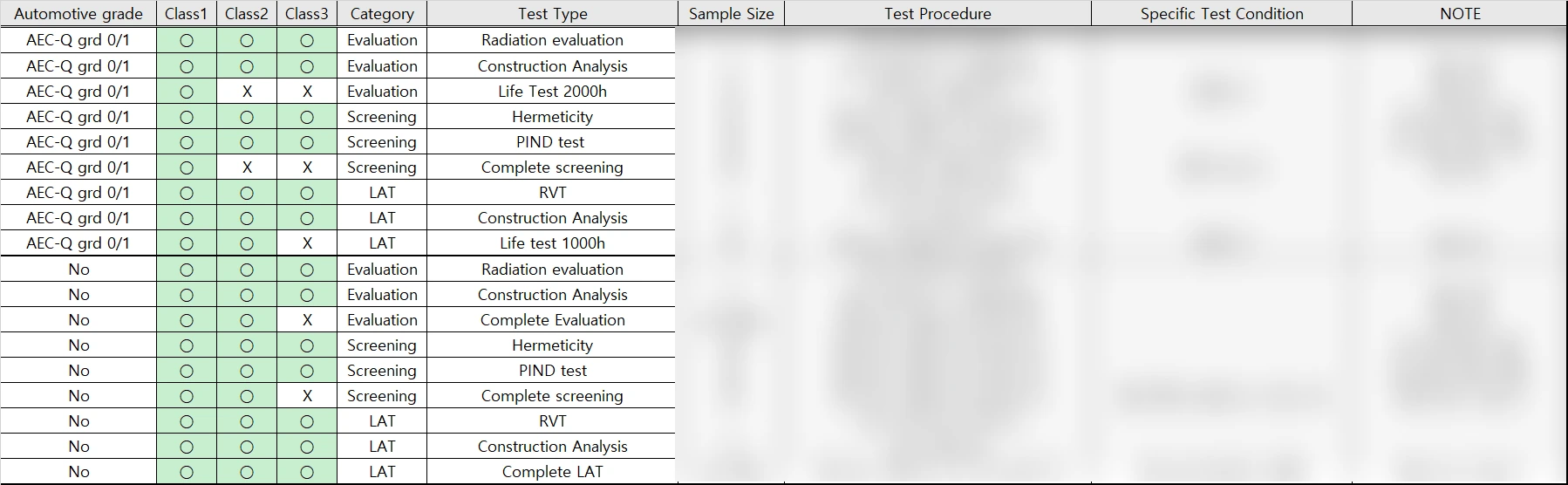

ECSS and ESCC define the selection, control, procurement, and usage requirements for EEE parts in space projects. They categorize parts into Class 1–3 by risk/assurance level and provide guidance on how to supplement up-screening when using AEC-Q parts. ECSS specifies the overall test items for EEE components, while ESCC details the exact test requirements.

The table below summarizes up-screening items per ECSS-Q-ST-60-13C Rev.2 (2025-04-30).

*AEC-Q: Automotive Electronics Council standards for ensuring the reliability and quality of automotive electronic components.

ESA mission classes balance different levels of assurance versus risk. Class 1 offers the highest assurance and lowest risk, while Class 3 offers the lowest assurance and highest risk. Procurement cost typically follows the same order (Class 1 highest, Class 3 lowest), but engineering mitigations can reduce total cost-of-ownership differences across classes. The appropriate class for a system or subsystem depends on project goals, definitions, and constraints.

Additional references include ECSS-Q-ST-30-11C Rev.2 (2021-06-23) for derating rules (component family load factors/limits) and ECSS-Q-ST-60-15C Rev.1 (2025-03-20) for Radiation Hardness Assurance (RHA) project requirements. ESA also maintains the qualification lists: ESCC QML (Qualified Manufacturers List) and QPL (Qualified Parts List).

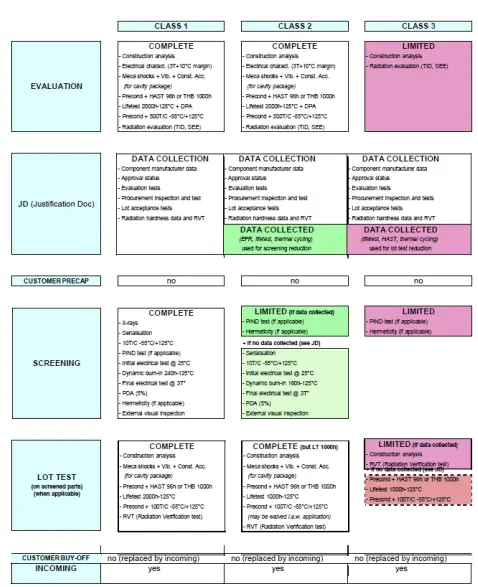

The table below shows the key differences by class from ECSS-Q-ST-60-13C Annex G.

ESA COTS Guidelines

The ESA COTS Guidelines are a recommendation (not a standard) covering classification, procurement, application, and testing when using COTS within space equipment/subsystems/systems. The document stratifies COTS usage by system criticality and provides practical guidance for managing radiation and reliability risks across design, test, and operations.

Risk domains and grades are split into Q0 (covered by ECSS) and Q1/Q2 (outside standard requirements).

- Q0 is subdivided into Class 1–3. COTS EEE follows ECSS-Q-ST-60-13C, while high-reliability EEE follows ECSS-Q-ST-60C. Same trace code (lot homogeneity) is expected, and ground evaluation/lot approval maintains representativeness.

- Q1/Q2 aim for homogeneity but cannot guarantee it; thus, test representativeness may be limited. The guidelines strongly recommend best practices and design mitigations.

Q2

Most cost-effective but highest risk acceptance. Targets TID < 5 krad(Si) with typical mission duration of months (usually < 1 year). Operation in LEO below ~1000 km is recommended with OFF states through SAA and polar passes. Destructive SEE risks (SEL, SEGR, SEB) are relatively high; design mitigations are assumed.

Q1

Lower risk than Q2 but at higher cost. Typical TID ~10–15 krad(Si) and mission duration of several years (usually < 5 years). From Q1 upward, SEE risk drives more concrete evaluation and operational criteria.

Q0

The highest-assurance grade under ECSS. Same trace code is guaranteed, and parts are classified Class 1–3 by risk/reliability. COTS under Q0 applies ECSS-Q-ST-60-13C; high-reliability parts under Q0 apply ECSS-Q-ST-60C.

United States: NASA / DoD (MIL) Framework

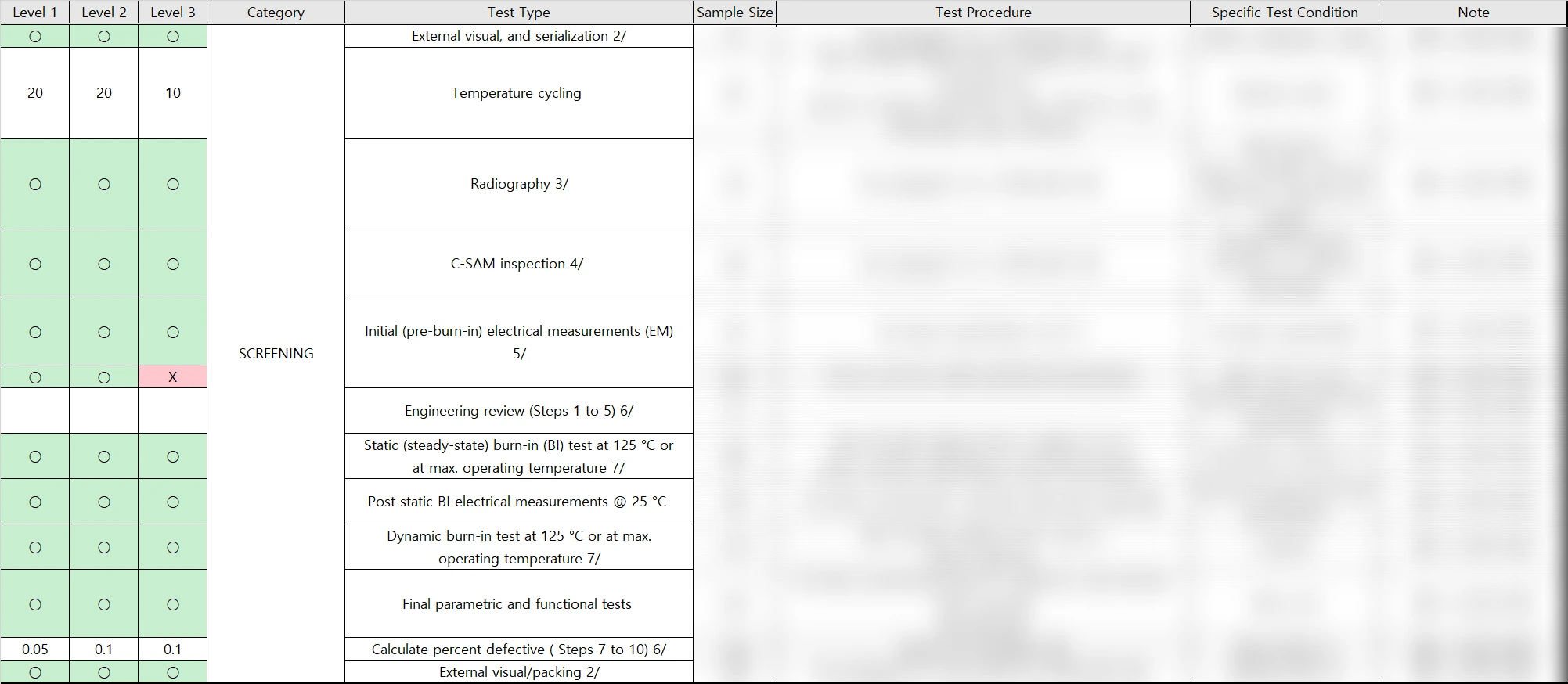

NASA’s EEE parts management is defined by EEE-INST-002 and U.S. Military Standards. EEE-INST-002 specifies criteria for part selection/procurement, screening, and derating. The table below summarizes up-screening items per EEE-INST-002; applicability and limits vary by mission level (Level 1–3).

Mission levels per EEE-INST-002:

Level 1

The highest reliability and lowest risk are required. Active devices must have Radiation Hardness assessed; if data are unavailable, radiation testing is required. Typical mission duration: ≥ 5 years.

Level 2

Targets low-to-moderate risk, balancing cost constraints and mission objectives. Active devices still require radiation hardness assessment, and testing is required if data are lacking. Typical mission duration: 1–5 years.

Level 3

Parts lack formal reliability evaluation/screening/qualification, so inherent or unknown risk is high. Flight heritage and stable design/material/process baselines are limited, and data from one LDC (Lot Design Code) may not generalize to another. Intended for missions where high-risk parts are acceptable (e.g., CubeSats, low-cost satellites). Radiation hardness must still be assessed; testing is required if data are lacking. Typical mission duration: < 1–2 years.

EEE-INST-002, originally issued in 2008, does not fully reflect the latest New Space requirements. NASA has therefore updated NASA-STD-8739.11 (not yet formally released at the time of writing). Notably, the revision introduces Level 4, which appears to address broader use of COTS parts.

While NASA-STD-8739.11 includes up-screening topics, detailed test methods and limits reside in the MIL series. For example, microcircuit-level tests are in MIL-STD-883, and discrete semiconductor reliability/performance (transistors, diodes, rectifiers, power semiconductors) for military and aerospace use are covered by MIL-PRF-19500.

In short, NASA-STD-8739.11 provides the higher-level framework for part selection and management, while MIL-STD/MIL-PRF documents define the concrete test procedures and conditions—together forming a complementary system.

[1] European Space Agency (ESA), Guidelines for the Utilization of COTS Components and Modules in ESA, ESA-TEC-TN-021473, Issue 3.0, 21 Oct 2024, Noordwijk, The Netherlands.

[2] NASA Goddard Space Flight Center, EEE-INST-002: Instructions for EEE Parts Selection, Screening, Qualification, and Derating, Rev. D, Greenbelt, MD, USA, Apr 2018.

[3] ECSS, ECSS-Q-ST-60-13C: Commercial Electrical, Electronic and Electromechanical (EEE) Components, 21 Oct 2013.

[4] ECSS, ECSS-Q-ST-60C Rev.2: Space Product Assurance – EEE Components, 21 Oct 2013.

|

|